Corrugated Carton Box Making Machine Printing Slotting Die Cutting Machinery

Carton printing equipment parameter configuration scheme The overall machine is designed and built with high precision,

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Customize all models |

| Warranty | 1 Year |

| Certification | ISO9001, TUV, GMP, ISO, CE |

| Application | Commodity, Machinery & Hardware, Textile, Alcohol, Toy, Chemical, Apparel, Gifts & Arts, Medical, Food |

| Driven Type | Electric |

| After-Sales Service Provided | Overseas Service Center Available |

| Type | Automatic Carton Making Machine |

| Automatic Grade | Automatic |

| Transport Package | Shipping |

| Specification | Customize any model |

| Origin | China |

| HS Code | 8441309000 |

| Production Capacity | 500/Years |

Product Description

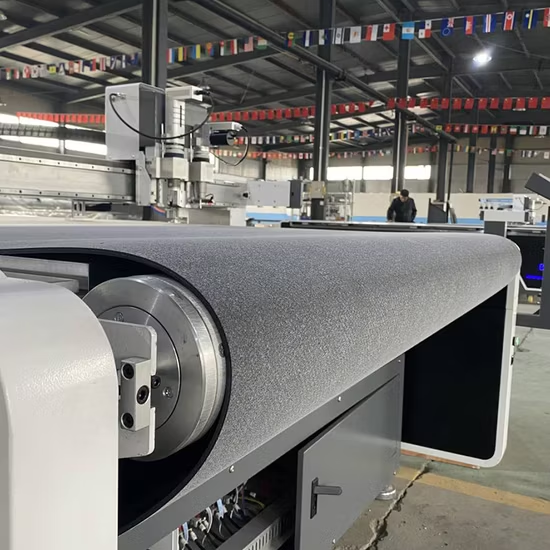

Carton printing equipment parameter configuration schemeThe overall machine is designed and built with high precision, intelligence, and security.All transmission rolls are made of high-quality thick wall seamless steel, deep hole boring, surface grinding and hard chrome plating.Spray paint process: parts after derusting - phosphating - spray paint - paint, can make the outer box to rust, paint surface hardening, play a beautiful role in corrosion resistance.Gear material 20Crmnti, straight tooth structure, quenching and tempering, increase hardness, grinding, Rockwell hardness & GT; 60 degrees.Using a tightener to connect the ring reduces center wear, amplifies virtual position, and maintains long-term printing registration.Each unit automatically returns to zero, and the erasures automatically lock the machine.Controlled by a touchscreen computer, they can store orders, up to 1,000 . Quick exchange order, more convenient operation.Each unit is equipped with an emergency stop switch, which stops each unit from moving internally, ensuring the safety of internal operators.A monitor monitor is installed on the paper receiving side of the equipment, allowing workers to observe the situation of paper collection.Each unit of the machine is automatically or independently separated, making it easier to operate, and keeps ringing when walking to ensure the safety of the operator.wallboard material HT250 cast iron, medium frequency tuning internal stress, increase density hardness, a large machining center in pairs processing.Equipment Highlights:1, servo leading edge feed, feed length is controllable, feed accurate without error.2. Fast roll changing device for paper feeding roller, safe, fast and improve work efficiency. Save roll change time.3, uniform ink transmission system, adopts full gear transmission, reduce noise, enhance transmission tightness, improve the speed and stability of the machine, improve the printing accuracy and overprinting accuracy.4, lack of ink alarm device, to prevent the lack of ink and waste cardboard, effectively reduce waste productivity.5, Taiwan technology oil surface automatic balancing device, unified oil level, prevent the lack of lubricating oil unit or overflow.6, one button automatic combination function, simple and quick operation, easy to replace the printing plate.Device configuration details:I. Paper feeding unitNegative pressure adsorption multi-row wheel feeding structure, no damage to cardboard, and effectively overcome the cardboard warping, improve the accuracy of paper feeding, make high and low speed paper feeding more accurate.Intelligent adjustment of the paper feeding trip, reduce the pressure of the paper roller.Frequency converter controls the vacuum airflow and pressure to match the cardboard size.Positioned by the leading edge, reduce paper feeding error, improve the accuracy of paper feeding and slotting.Improve the stability of high-speed operation, reduce noise and mechanical vibration.The position of left and right baffle adopts electric digital control.The back support cardboard frame electric control before and after, speed up the setting speed.Adjust the clearance of front board manually.With continuous or separated sheet feeding function.It is equipped with a paper feeding counter to set and display the production quantity.1. Feed paper to upper and lower rollersThe roller: soft cots, diameter φ155.35.Under roll: steel roll diameter φ154.77, surface Xian straight line, and then hard chrome plating.2. Machine clutch, automatic zero deviceThe drive shaft is attached with friction clutch to avoid damage to the machine by mistake.The host motor start protection device (the machine is not locked, the host can not start running).The paper feeding unit, printing unit and slotting unit are automatically zeroed by encoder.(4) General carton using automatic zeroing device, trial printing can be adjusted to the correct position, reduce cardboard waste.Two, printing unit1. Printing roller1) Printing roller φ392.8, the thickness of the raw material wall is 14mm (including the diameter of the plate is ¢528.6)2) Seamless steel pipe material, surface grinding, hard chrome plating.3) Balance correction, smooth operation.5) Reel groove plate, the use of infinite wire wheel self-locking device, so that the plate alignment accurate.6) full version of the groove, applicable to 9mm×3mm version.7) Loading and unloading printing plate, foot switch electric control positive and negative rotation.9) Orientation adjustment interface; With automatic zeroing, automatic plate setting and locking recovery printing position and other functions.2, imprint roller1) Seamless steel pipe of high quality, boring by deep hole boring machine, and made of hard chromium with fine grinding degree.2) imprint stick diameter of 154.77mm wall thickness 20mm.3) Adopt high frequency hot charging and hot charging welding.3) Balance correction, remove centrifugal force, smooth operation.4) The gap of the press roll is printed, and the turbine box is manually adjusted by self-locking handle, and the dial is displayed. The adjustment range is 0-11mm.3 paper guide roller1) The paper guide shaft is made of thick-walled steel pipe with a diameter of 99 mm and a wall thickness of 20 mm. Dynamic and static balance correction, precision grinding, surface hard chrome plating; The paper guide shaft is equipped with two paper guide wheels with carved surface. The paper guide wheels are fast and manual horizontal adjustment of rack type.2) The lower press roll of guide paper is made of seamless steel pipe, with a diameter of 154.77mm and a wall thickness of 20mm. Dynamic and static balance correction, precision grinding, hard chrome plating on the surface, quenching and tempering of the shaft core parts, and hot sleeve technology make it have strong fatigue resistance and toughness.3) Paper guide roll clearance, manual adjustment of turbo box self-locking, dial display, adjustment range 0-11mm.3. The anilox roll1) The roller adopts Changzhou Haili or Yudong company products, the net hole is neat, the net wall is neat, the cable can choose 200-280 lines/inch.2) the net grain rod diameter is ¢213.5mm..4) roller clearance screen display handle type manual adjustment, adjustment range 1-8mm,5) Pneumatic lifting of the net roller, to prevent repeated ink printing plate and short shutdown, the ink in the net roller point dry.6) the roller gap adopts self-locking structure.The inking roller1) The iron core is made of high-quality seamless steel pipe with a diameter of 168 mm and a wall thickness of 25 mm. Shaft head forging hot sleeve process, dynamic and static2) Balance correction, smooth operation.2) The surface is wrapped with wear-resistant rubber, the diameter of the rubber surface is 200mm, the thickness of the rubber surface is 16mm, the height of the rubber roller is parabolic form, and the ink transfer effect is good after special precision grinding.3) When the main machine stops, the cots are driven by reducer motor and run automatically.4) The gap between the roller and the roller is adjusted by manual self-locking of the turbine box. The adjustment range is 0-6mm.5, phase adjustment mechanismPlanetary gear construction.The printing phase adopts computer and electric digital control.The PRINTING ROLLER ADOPTS FREQUENCY conversion DRIVER TO adjust THE phase, THE speed of ZEROing and adjusting the plate is fast, and the adjustment accuracy is high.(4) Automatic reset system of locking machine after wiping plate7. Ink cycle structureThe use of pneumatic diaphragm pump, stable ink supply, simple operation and maintenance.The rubber roller and roller is not closed, pneumatic ink pump can not pump ink.abnormal ink supply, warning light display.(4) ink screen, filter impurities.stainless steel ink tank. Automatic cycle cleaning and automatic inking.6) The equipment is equipped with a lack of ink alarm system.8 Printing phase fixing devicePneumatic brake mechanism, when the unit is separated to adjust the phase or cleaning, the brake mechanism limits the gear rotation,Keep the original tooth position fixed point.The power transmission of the pressure roller is driven by CAM bearing, the wear is small and the transmission is more stable.(3) with automatic cleaning ink saving system.9. The final color group paper can increase the prepressing device, the paper shaft is the prepressing shaft, the prepressing wheel is the fast manual transverse adjustment, and the die cutting part is combined with the double prepressing or double pressing line device, to solve the problem of paper blasting or molding is not good; Clearance turbo box self-locking manual adjustment, adjustment range 0-11mm.Four. Die slotting unit - Six axis drive: prepressing, line pressing, single axis double knife slotting (mechanical linear velocity compensation)1. The gear housing is a streamlined housing.2. Die cutting roller2.1 The die cutting roller body is made of seamless steel pipe, hot sleeve forging shaft head, lock shaft structure, dynamic and static balance correction, and hard chrome plating on the surface.2.2 Die cutting roller diameter:Ф outer diameter 389 mmContaining glue outer diameter ф 405mm2.3 The eccentric gear and wall of die cutting cots are equipped with special steel sleeve, and the shaft head is equipped with cylinder lock mechanism, which greatly increases the service life of eccentric gear and the stability of cots.2.4 The surface is wrapped with Eureka glue. Eureka glue (made in Italy) is installed in buckle structure for easy replacement.2.5 Rubber roller adopts mechanical differential transmission to make it automatically move around, and the amount of horizontal movement is plus or minus 30mm, which can make the rubber sleeve wear evenly.Extend service life.2.6 The gap of die cutting roll can be adjusted manually, or automatically pressurized or detached with the feed of the main machine. The adjustment range is 0-15mm.2.7 Die cutting rubber pad is equipped with automatic turning mechanism, so that the rubber pad can be turned many times, repeated use.2.8 Die cutting cots are equipped with mechanical linear speed compensation function. Can also choose independent variable frequency motor line speed compensation function.3 preloading wheel3.1 The upper and lower preloading wheel shaft is made of thick-walled steel, the surface is plated with hard chromium after grinding, and the dynamic and static balance is corrected. It is equipped with four groups of preloading wheels.3.2 Diameter of preloading wheel shaft: 110mm, wall thickness 30mm.3.3 The appearance of the upper prepressing wire wheel is wrapped with Eureka glue, which does not harm the cardboard. Eureka rubber and prepressing wire wheel adopts detachable structure for easy replacement.3.4 Intermittent pre-pressure paper, turbo box self-locking electric adjustment, dial display, adjustment range 0-11mm4 ti4.1 The shaft of the upper and lower line pressing wheel is made of thick-walled steel, the surface is plated with hard chromium after grinding, and the dynamic and static balance is corrected. It is equipped with four sets of line pressing wheel.4.2 Diameter of wire pressing wheel shaft: 110mm wall thickness 30mm4.3 The appearance of the wire pressing wheel is wrapped with Eureka glue, which does not harm the cardboard. The Eureka rubber and the wire roller are detachable for easy replacement.4.4 Wire pressing through the paper gap, the turbine box self-locking manual adjustment dial display, the adjustment range is 0-11mm.5 Slotting tool shaft5.1 Slotting cutter head shaft is made of thick wall steel, precision grinding twice, dynamic and static balance correction, hard chrome plating on the surface, stable movement.5.2 Diameter of slotting cutter shaft: 156mm. Wall thickness: 30mm.5.3 The material of slotting knife is imported from Austria, the width is 7mm, the hardness is HRC60-63, and the toughness is excellent.5.5 The upper and lower slotting cutter head adopts the structure of the closed type air avoidance cutter head, the cutter head is stable, not easy to stick the cutter and can achieve a smaller slot spacing; Splint structure is adopted for the linkage of upper and lower cutter head, prepressing and line pressing wheel. Self-lubricating wear-resistant copper block can be ground repeatedly and used, greatly reducing the cost of wearing parts.5.6 Slotting cutter head, prepressing wheel and line pressing wheel are synchronized with linear guide rail, precision lead rod and linkage plate balancing mechanism. The upper and lower linkage plate shaft of precision special turboworm box is directly connected for smooth and precise transmission.5.7 Separate PLC with LCD touch screen, servo motor drive, computer calculation control, horizontal movement, phase, box height can realize automatic ordering, order memory, automatic execution of order retrieval, digital explicit electric adjustment or data input automatic adjustment; Box height is adjusted synchronously for four cutter head.5.8 Slotting through the paper gap, the turbine box self-locking manual adjustment, dial display, adjustment range 0-11mm.5.9 The slotting cutter is movable, which can handle larger cartons with double packing specifications.5.10 Lighting is installed above the slotted part to facilitate night work.When the machine is separated or the phase is adjusted, the pneumatic brake mechanism limits the machine rotation and keeps the printing position unchanged.6. Phase adjustment6.1 Phase adjustment adopts the double-load adjustable clearance planetary gear structure, which can be adjusted accurately by 360°.6.2 Die-cutting phase digital display electric, automatic zero, automatic reset, can also be adjusted according to the whole machine automatic arrangement memory.6.4 Phase fixed pneumatic brake mechanism, when the machine moves and separates, keep the gear position unchanged.Five, transmission gear1. Main drive gear1), using 20CrMnTi alloy steel, carburizing and quenching treatment, grinding teeth. High strength and good toughness.2), six precision, hardness HRC58-62, wear resistance, can achieve long-term printing overprinting precision.2. Keyfree connection1) Tensioning the connecting ring, strong overload, durable, stable and reliable3, lubrication1. Each unit is lubricated by oil pump to realize circulating spray lubrication.2. Each tank is equipped with oil surface balancing device to balance the height of oil surface.

| Machine design production speed | 200pcs/min | |

| Machine economy production rate | 0-180pcs/min() | |

| Maximum feed size | 2600mm×1200mm | |

| Minimum feed size | 450mm×320mm | |

| Maximum printing area | 2400mm×1200mm | |

| Standard plate thickness | 7.2mm | |

| Accuracy of paper feeding alignment | ±1mm | |

| Precision of printing registration | ±0.5 mm | |

| Precision of mould cutting groove registration | ±1mm |

| 1. Printing roller, roller bearing | NTN/ others | all | |

| 2. Ac contactor | Siemens. | all | |

| 4. Intermediate relay | chint | all | |

| 5. Heat protector | chint | all | |

| 6. Button switch | schneider | all | |

| 7. Emergency stop switch | schneider | all | |

| 8. Switch the power supply | in | all | |

| 9. The circuit breaker | chint | all | |

| 10. Proximity switch | Times funing | all | |

| 11. The flow again | jinhua | all | |

| 12. PLC | in | six | |

| 13. The encoder | Xin ling | all | |

| 14. The transformer | chint | ||

| 15. Travel switch | chint | all | |

| 16. Computer touch screen | Kunlun Tongtai 7 inches | three | |

| 17. Keyfree connection ring | Xianyang chaoyue | all | |

| 18. Pneumatic diaphragm pump | Wenzhou DE - | 1 | |

| 19. The frequency converter | Suzhou Wei de Weno | all | 2 |

| 20. Pneumatic solenoid valve | Day Mr. | all | |

| 21. Die cutting rubber pad | EXM389 | all | |

| 22. The anilox roll | Dalian metal | Article 1. | |

| 23. The gear | shandong | all | |

| 24. The fan | Positive force | 1 | |

| 25. Rubber roller | JiZhou hengfeng | all | |

| 26. The ink pump | DE - | all | |

| 27. The belt | WeiShi | all |